For small fabricators operating in sectors like custom metalwork, HVAC installation, and small-batch industrial component production, labor efficiency directly impacts profitability. Tube processing—including flaring, expanding, beading, and threading—is a core task for these operations, but traditional manual methods have long been a bottleneck. Time-consuming, labor-intensive, and prone to human error, manual tube processing eats into productive hours while compromising consistency. In contrast, Tube end forming machines have emerged as a transformative solution for small fabricators, slashing labor time, reducing costs, and elevating quality—all while remaining accessible to operations with limited floor space and budget constraints.

The Labor Burden of Manual Tube Processing for Small Fabricators

Small fabricators face unique challenges that amplify the inefficiencies of manual tube processing:

First, excessive time per task. Manual tube forming relies on hand tools, hydraulic hand pumps, or basic mechanical presses that require painstaking precision. A single tube end—whether flaring for HVAC connections or beading for industrial fittings—can take 5–10 minutes to complete, with additional time spent on measuring, adjusting tools, and correcting mistakes. For small fabricators handling 50–200 tubes per day, this translates to hours of labor dedicated solely to tube processing, diverting resources from other critical tasks like assembly or customer service.

Second, high skill dependency and inconsistency. Manual processing demands experienced workers who can judge pressure, alignment, and form by feel—skills that take months to develop. Even with skilled labor, consistency is elusive: variations in hand pressure or tool alignment lead to inconsistent tube end profiles, with dimensional deviations often exceeding ±0.1mm. This inconsistency results in rework (up to 15% of manual runs require adjustments) and rejected components, wasting both labor and material costs.

Third, physical strain and labor limitations. Repetitive manual forming tasks cause fatigue and muscle strain, leading to reduced productivity over shifts and increased risk of workplace injuries. For small fabricators struggling with labor shortages—a common industry challenge—losing even one worker to injury or burnout can disrupt operations entirely. Additionally, manual processing limits scalability: small fabricators can’t take on larger orders without hiring additional skilled labor, which may not be financially feasible.

Compounding these issues are tight profit margins for small operations. Manual processing’s labor costs, material waste, and rework expenses eat into already limited budgets, making it difficult to compete with larger manufacturers or meet customer demands for faster turnaround times.

Core Advantages: How Tube End Forming Machines Cut Labor Hours

Tube end forming machines address small fabricators’ pain points by delivering three labor-saving benefits that transform tube processing:

Dramatic Speed Improvements: Automated and semi-automated tube end forming machines complete tasks in a fraction of the time required for manual processing. A tube end that takes 5–10 minutes to form manually can be finished in 10–30 seconds with a machine—cutting processing time by 90% or more. For small fabricators handling 100 tubes per day, this translates to saving 8–15 hours of labor weekly, freeing up staff to focus on higher-value work like custom design, order fulfillment, or customer support. Even semi-automatic models (the most budget-friendly option for small shops) offer significant speed gains, with quick setup times (5–10 minutes per job) and continuous processing capabilities.

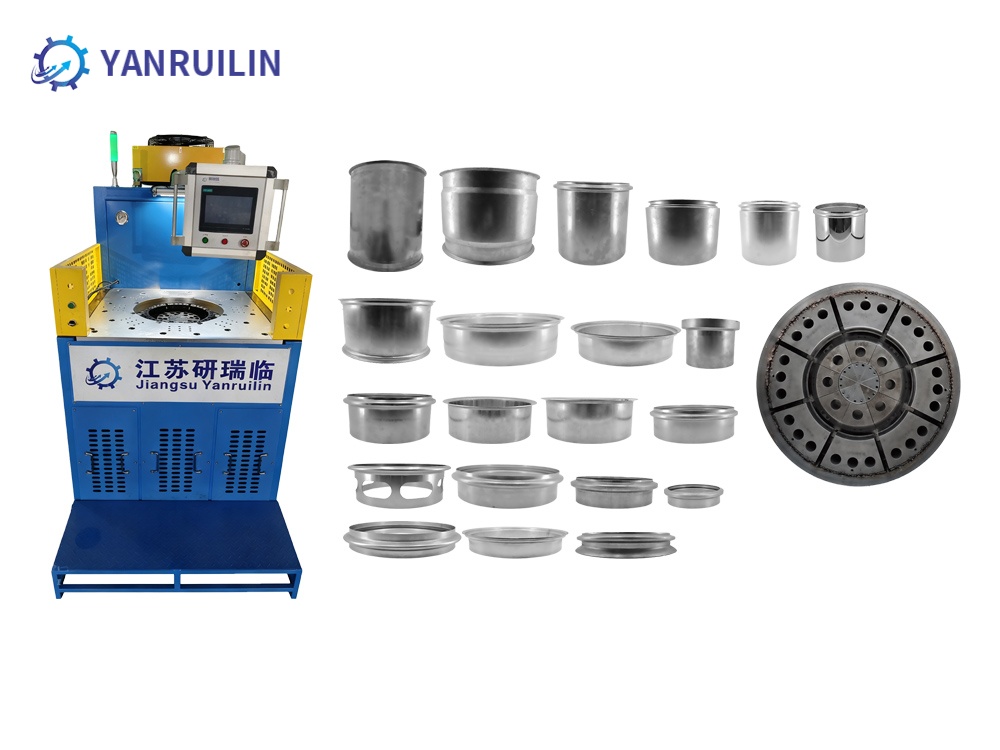

Tube end forming machines

Consistency That Eliminates Rework: Tube end forming machines deliver uniform, precise results with tolerances as tight as ±0.02mm—far exceeding manual capabilities. Equipped with fixed tooling, programmable controls, and pressure sensors, they replicate the same form across every tube, eliminating human error and variations. This consistency reduces rework rates to less than 1%, saving hours of labor that would otherwise be spent correcting flawed components. For small fabricators, this not only cuts labor costs but also improves customer satisfaction by delivering reliable, high-quality parts.

Reduced Skill Dependency and Physical Strain: Machines simplify tube forming to intuitive, button-operated tasks that require minimal training—no specialized skills or "feel" for the work. This allows small fabricators to use less experienced staff for tube processing, addressing labor shortages and reducing training costs. Additionally, automated operation eliminates repetitive manual labor, reducing fatigue and injury risks. Staff can operate multiple machines simultaneously or handle other tasks while the machine runs, further maximizing labor efficiency.

Additional Benefits for Small Fabricator Operations

Beyond labor savings, tube end forming machines offer advantages tailored to small shops’ unique constraints:

Space Efficiency: Compact models (tabletop or floor-standing with small footprints) fit easily into tight workshop spaces, requiring no major facility modifications. Many semi-automatic machines weigh less than 100kg, making them portable for on-site processing (e.g., HVAC installation jobs).

Budget-Friendly Cost of Ownership: While initial investment varies, entry-level semi-automatic machines are accessible for small fabricators, with quick ROI (return on investment) typically achieved within 6–12 months through labor and material savings. Low maintenance requirements (regular lubrication and tool checks) keep long-term costs manageable.

Flexibility for Custom Orders: Small fabricators thrive on custom work, and tube end forming machines adapt easily to diverse needs. Modular tooling allows switching between forming tasks (flaring, expanding, beading) in minutes, while programmable controls store custom settings for repeat orders. This flexibility enables small shops to take on a wider range of projects without sacrificing efficiency—from custom HVAC fittings to specialized industrial components.

Industry Trends Driving Adoption Among Small Fabricators

Several key trends are accelerating small fabricators’ shift from manual processing to tube end forming machines:

Labor Shortages: The manufacturing industry’s ongoing labor crunch has made it harder for small fabricators to find and retain skilled workers. Machines reduce reliance on specialized labor, allowing shops to operate with smaller teams or less experienced staff.

Customer Demand for Faster Turnaround: In a competitive market, customers expect quicker delivery times for custom orders. Machines enable small fabricators to process orders in days instead of weeks, meeting tight deadlines and winning more business.

Growth of Niche Markets: Small fabricators are increasingly targeting niche sectors like custom furniture, recreational vehicles, or small-scale industrial equipment—markets that require flexible, efficient tube processing. Machines support this growth by handling diverse orders quickly and cost-effectively.

Cost Pressures: Rising labor costs and material prices have squeezed small fabricators’ margins. Machines reduce both labor expenses and material waste (precision forming minimizes scrap), improving profitability.

A Game-Changer for Small Fabricator Competitiveness

For small fabricators, the choice between manual tube processing and tube end forming machines is a decision about efficiency, profitability, and growth. Manual methods trap shops in a cycle of high labor costs, inconsistent quality, and limited scalability—while machines unlock hours of weekly labor savings, improve quality, and open doors to new business opportunities.

As small fabricators face increasing competition from larger manufacturers and evolving customer demands, tube end forming machines have become more than a luxury—they are a necessity for staying competitive. By cutting labor hours, reducing costs, and delivering reliable quality, these machines empower small shops to punch above their weight, thrive in niche markets, and build sustainable businesses. For small fabricators ready to escape the grind of manual tube processing, the investment in a tube end forming machine is an investment in future success.

This website uses cookies to ensure you get the best experience on our website.

Comment

(0)